The hand-held measuring device SITA CleanoSpector is highly suited for cleanliness inspection of parts to assure product quality as well as follow-up processes such as adhesive bonding, coating, welding, hardening and bonding.

Unwanted, filmic contamination such as oils, greases, cooling lubricants and release agents are measured by determining the fluorescence intensity.

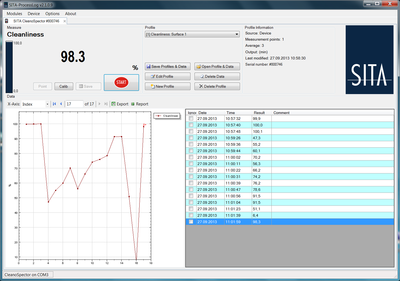

The SITA CleanoSpector is easy to use and optimal for quality assurance directly in the manufacturing process.

Features:

Mobile and robust device for flexible use at the process and in the laboratory

Intuitive operation: simple and fast operation at the push of one button

Device with easy to handle sensor head and display unit enables measurment with a small contact area as well as different application possibilities

Check and adjustment with calibration standards